Before I enamel the ellipse I wan't to do some tests. For this I'm cutting out some small rectangles 74mm x 52mm (this is A8 paper size).

First I cut some strips of steel slightly oversize, so about 52.5mm wide, I've got about 4 sheets together here:

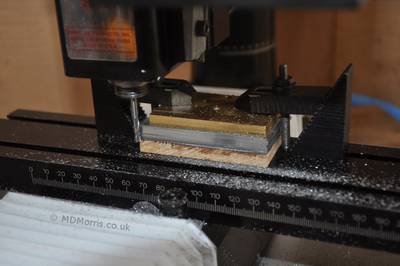

The pieces are firmly clamped at the ends and raised off the machine table using some laminate flooring off-cut. I probably should have clamped something on top as I did get a bit of chatter mid-way down the strip - but it wasn't much of a problem.

Next I cut the strip into sections, again slightly oversize, each to 74.5mm in length. For this I used a band-saw with a stop set to cut the right length.

All the brass off-cuts in the band-saw vice here are just to balance the vice-jaw. It's easier just to cut one at a time otherwise the clamping is too fiddly.

Once the rectangles are cut I sandwich them together and mill them to the exact dimensions all at once:

It takes a bit of juggling with the clamping

,

,

and I get a set of ten A8 sized steel pieces:

.

.

These will be good for testing the enamelling process, and to see if rounding the edges produces any significant difference to the adhesion of the enamel at the edge.